The Transformative Power of Rapid Prototyping Service

Innovation in the modern marketplace is defined not just by ideas but by execution. When it comes to bringing an idea from concept to reality, the process of rapid prototyping has emerged as a pivotal strategy in various industries. At deepmould.net, we specialize in providing unparalleled rapid prototyping services that cater to diverse business needs.

What is Rapid Prototyping?

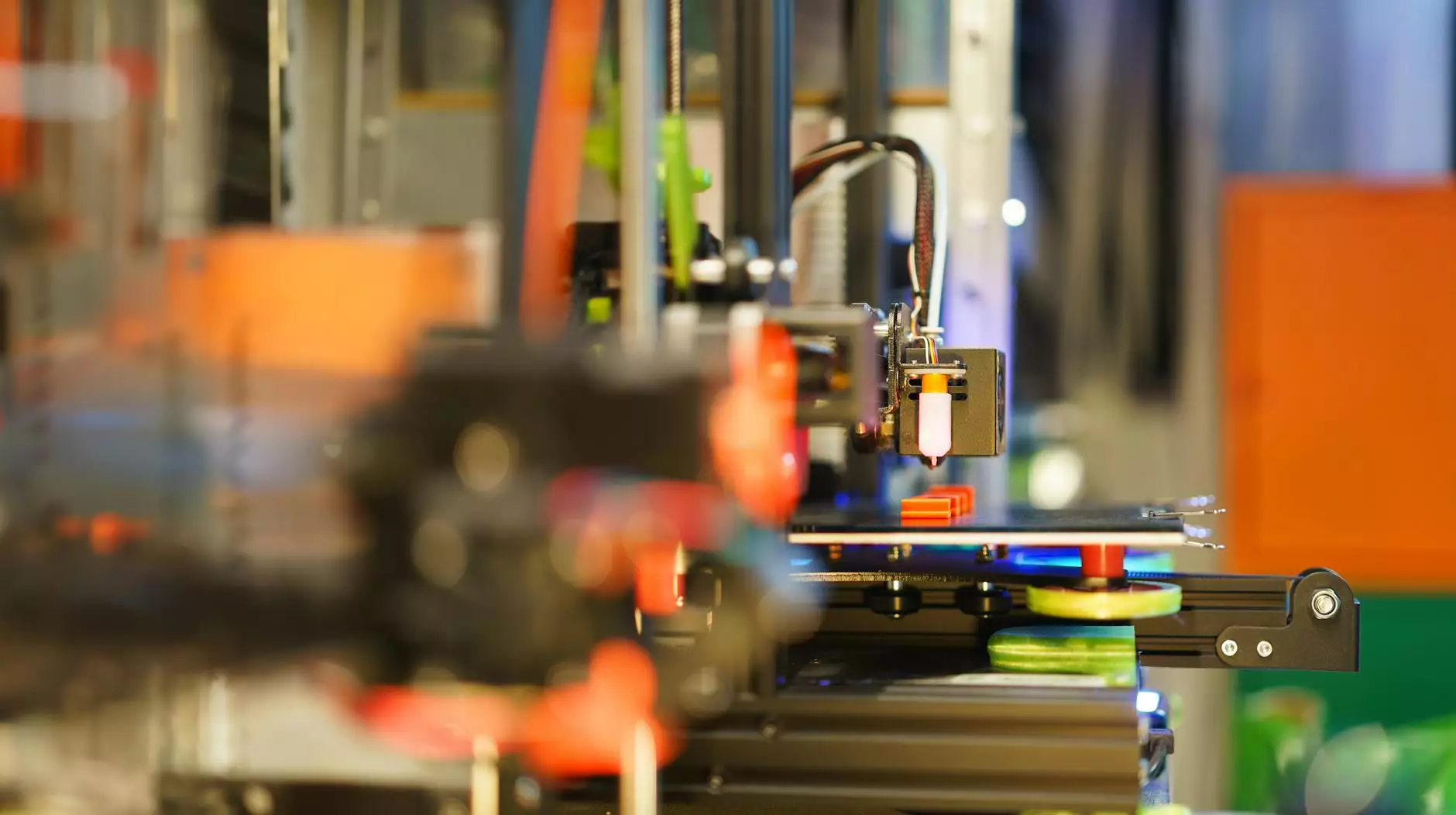

Rapid prototyping is a fast and efficient method of creating a scale model or prototype of a product using 3D printing, CNC machining, and other techniques. This service plays a crucial role in product design and development, enabling businesses to validate designs, assess functionality, and iterate quickly on their ideas.

Key Benefits of Rapid Prototyping Service

- Speed: Rapid prototyping drastically reduces the time from concept to physical product, allowing businesses to accelerate their product development cycles.

- Cost-Effective: By identifying design flaws early in the development process, companies can save significant costs associated with later-stage changes.

- Enhanced Collaboration: Rapid prototypes provide a tangible representation of ideas, fostering collaboration among team members, stakeholders, and potential customers.

- Improved Design Quality: Early testing leads to better design choices and enhanced product quality, ultimately leading to greater customer satisfaction.

- Flexibility: The technology allows for modifications to be made quickly based on feedback, ensuring that the final product aligns closely with initial intentions and market demands.

Applications of Rapid Prototyping Service

The applications of rapid prototyping services span multiple industries. Here are some prominent sectors that benefit significantly:

1. Aerospace and Automotive

The aerospace and automotive industries rely heavily on precise engineering and rigorous testing. Rapid prototyping is vital here for creating complex parts and conducting simulations to ensure safety and efficiency.

2. Medical Devices

In the medical field, the ability to quickly prototype surgical tools, implants, and device housings allows for rigorous testing and validation. This ensures compliance with health regulations and enhances patient safety.

3. Consumer Electronics

With the fast-paced nature of consumer electronics, rapid prototyping helps companies like Apple and Samsung iterate on their designs swiftly, adjusting to market trends and consumer feedback in real time.

4. Architecture and Construction

The architectural industry utilizes rapid prototyping to create scale models of projects, enabling clients to visualize finished structures and aiding in the decision-making process.

5. Industrial Machinery

Machinery designers can develop functional components in a fraction of the time it would traditionally take, leading to increased innovation and efficiency in production processes.

How Does Rapid Prototyping Work?

The process of rapid prototyping can vary depending on the technology used. Generally, it involves the following steps:

1. Design

Using advanced CAD (Computer-Aided Design) software, engineers create a detailed digital model of the prototype. This digital representation serves as the blueprint for all subsequent steps.

2. Material Selection

Choosing the right materials is crucial in rapid prototyping. Options can range from plastics to metals, depending on the required strength, appearance, and functionality of the final product.

3. Manufacturing

The digital model is then translated into a physical prototype using various techniques such as:

- 3D Printing: Layering materials to build the prototype from the ground up.

- CNC Machining: Removing material from a solid block to achieve the desired shape.

- Injection Molding: Creating prototypes through a mold that can produce many identical parts quickly.

4. Testing and Iteration

Once the prototype is created, testing begins. Design flaws are identified and addressed. This iterative process continues until the final product meets specifications and performance criteria.

Why Choose DeepMould for Your Rapid Prototyping Service?

Expertise in Metal Fabrication

At DeepMould, we bring extensive expertise in metal fabricators, offering tailored solutions to meet your prototyping needs. Our cutting-edge technology and skilled professionals ensure that your prototypes are not only functional but also of the highest quality.

Commitment to Quality

Quality isn’t just a buzzword for us; it’s a commitment. We follow stringent quality control measures to make sure that every prototype we deliver meets your exact specifications and industry standards.

Customer-Centric Approach

Your needs drive our processes. We work closely with you to understand your vision and goals, ensuring that the final product aligns with your expectations. Our communication is transparent, and we provide real-time updates throughout the prototyping process.

Conclusion

The world of business is rapidly evolving, and companies must adopt innovative strategies to stay ahead. Rapid prototyping service is more than a tool; it’s a pathway to accelerated innovation, improved product quality, and enhanced collaboration. By investing in rapid prototyping, businesses can turn ideas into reality faster and more efficiently than ever before.

Choose DeepMould for your rapid prototyping needs, and let us help you in shaping the future of your product development processes today.